So it’s been a whole month since I posted anything, but things have been busy here behind the scenes and I simply didn’t get around to doing any updates in a while.

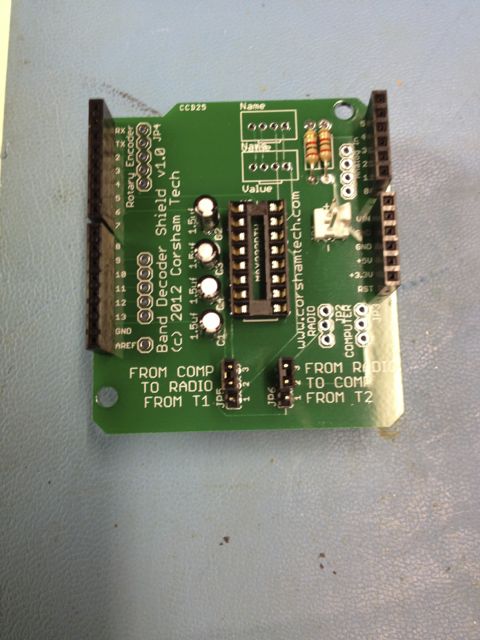

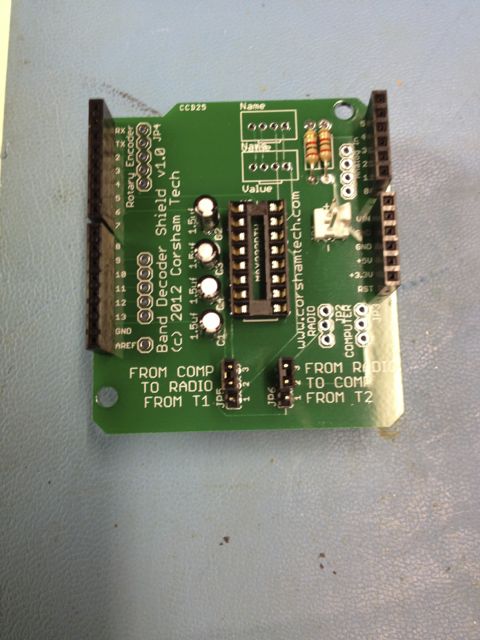

This is the prototype shield for the KX3 Band Decoder project:

A few more connectors need to be installed and then testing can begin. About a month ago the matching driver board was done, so this shield is the last piece. Speaking of the driver, I wanted an easy way to test production boards, so I built a one-off test jig:

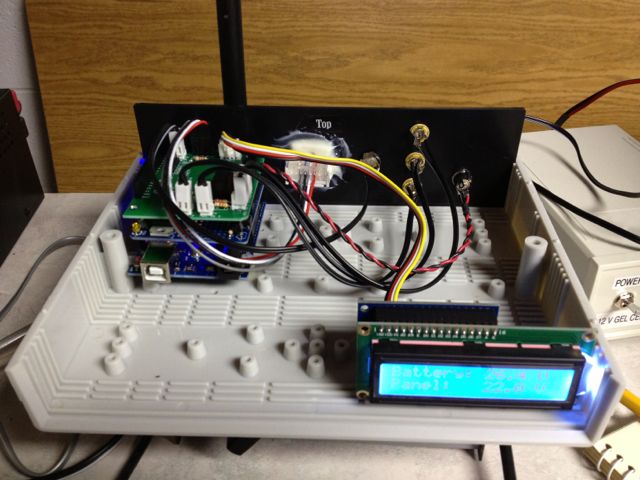

The board on top is the tester, while the lower board is the driver that is part of the actual product. Power is on (the red LED) and pin 4, 40 meters, is currently selected (green LED). In a final version, the driver is mounted with the DB-25 mounted to a rear panel.

The board on top is the tester, while the lower board is the driver that is part of the actual product. Power is on (the red LED) and pin 4, 40 meters, is currently selected (green LED). In a final version, the driver is mounted with the DB-25 mounted to a rear panel.

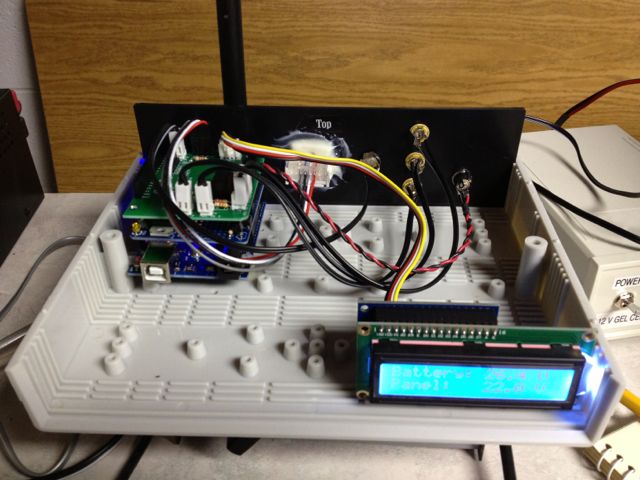

What else… oh, the green house monitor! We’ve had a monitor in Sui’s greenhouse for years now, but it draws a lot of current and the only working version isn’t in the workshop where I can add features, so I designed an Arduino shield that’s much simpler, has smaller code, and generally a better design. This will turn into a product eventually but for now this is the crude packaging I’ve been working on for our version:

The rear panel has inputs for three analog channels, one for measuring the output voltage of the solar panels, a one-wire interface for external temperature sensors (DS1820), and a connector for the SHT-11 temp/humidity sensor for use in the greenhouse. There is also an analog channel for monitoring the input voltage to the controller so we can remotely track the solar panel output versus the battery state.

The rear panel has inputs for three analog channels, one for measuring the output voltage of the solar panels, a one-wire interface for external temperature sensors (DS1820), and a connector for the SHT-11 temp/humidity sensor for use in the greenhouse. There is also an analog channel for monitoring the input voltage to the controller so we can remotely track the solar panel output versus the battery state.

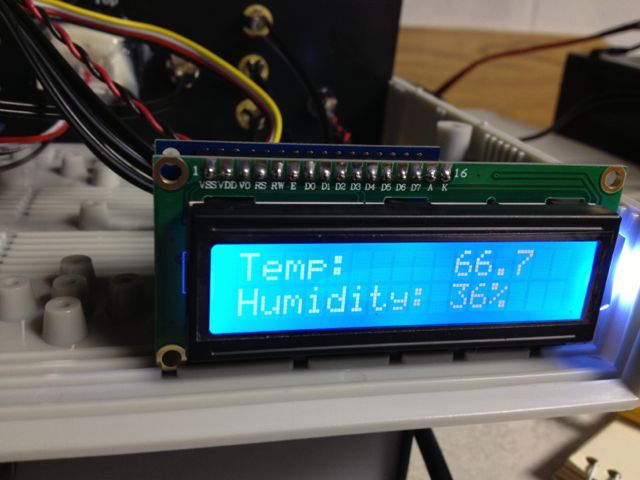

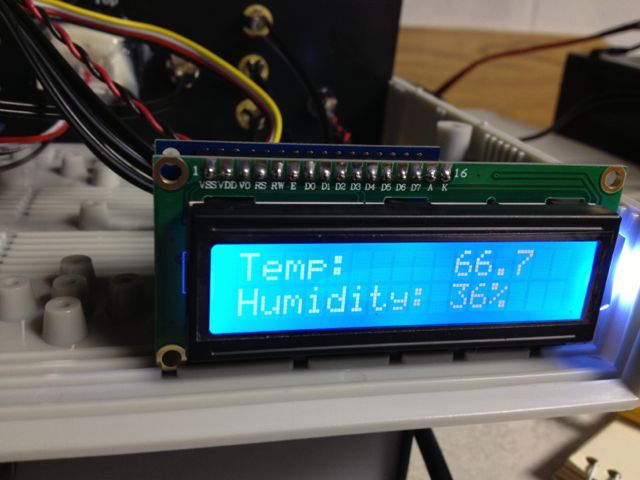

Every few seconds the display moves to the next set of values to display. The sensor is sitting in the workshop right now, which explains the 67 degree reading even thought it’s below freezing outside:

A new 60K RAM board for the KIM-1 has been sitting on the bench for weeks now; so much for my plans of building/testing over the holiday vacation.

A new 60K RAM board for the KIM-1 has been sitting on the bench for weeks now; so much for my plans of building/testing over the holiday vacation.

Yes, there are a lot of things on the bench, and we’re starting to make headway finally!